Your Goals

No matter whether you are in the Automotive industry, Whether you work in mechanical engineering, sensor technology or other production sectors, you are faced with the challenge of achieving high quality and production output at low cost.

At the same time, you need to react flexibly to changing market and customer requirements and ensure on-time deliveries. With our comprehensive services and products, we support you not only in production, but also in the Process optimisation, automation and data processing to maximise your efficiency, security and adaptability.

Your The challenges

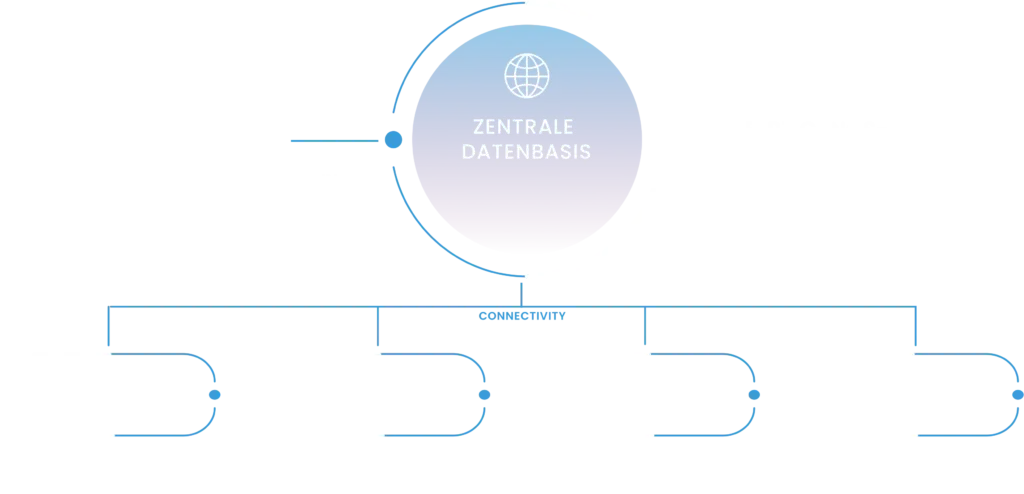

Production that has grown over the years with systems and machines often has no consistently automated data acquisition. This makes standardised data analysis and meaningful evaluation for necessary improvements to working methods, workflows and preventative measures on machines and in the process difficult. All this happens under high cost and time pressure. In addition, the Integration Other challenges include the disposal of legacy systems, ensuring data security and integrity, the lack of qualified personnel and training employees for new digital tools.

Analytics, Quality and maintenance

Your Solutions

Regardless of whether you work in the automotive industry, the Mechanical engineering, If you are active in the sensor technology or other production sectors, you are faced with the challenge of achieving high quality and production output at low cost.

At the same time, you need to react flexibly to changing market and customer requirements and ensure on-time deliveries. With our comprehensive services and products, we support you not only in production, but also in the Process optimisation, automation and data processing to maximise your efficiency, security and adaptability.

Yours Benefit

Digitalisation is revolutionising production operations by increasing efficiency and quality through automation and real-time monitoring, reducing costs and minimising waste. It enables flexible, scalable and customised production, promotes innovation through new business models and accelerated product development, and improves decision-making through data analysis and increased transparency. It also contributes to sustainability by optimising resource and energy consumption. Overall, digitalisation significantly strengthens the competitiveness of production companies.

All important points for your „time to market“ optimisation. Quality improvements and end-to-end product traceability allow you to improve product quality at every stage of production

Frequently asked questions (FAQs)

What challenges does GADV address with its solutions?

We support companies in achieving high quality and production output while simultaneously reducing costs - even with complex systems, time pressure and staff shortages.

In which sectors is GADV active?

We work together with companies from the automotive industry, mechanical engineering, sensor technology and other production sectors.

How does GADV help with the digitalisation of production processes?

We create a consistent digital production structure through automated data acquisition, process optimisation, integration of legacy systems and targeted training.

Why is continuous data collection so important?

It enables standardised data analyses and targeted process improvements, Predictive maintenance and a reliable basis for well-founded decisions.

What are the specific benefits of digitalisation for my production?

It increases efficiency and quality, reduces costs, increases transparency, enables scalable processes and strengthens your competitiveness - including the sustainable utilisation of resources.

What does "time to market" optimisation mean in the context of GADV?

We help to bring products to market faster and more efficiently - through digital processes, automation and flexible production control.

Does GADV also support the integration of existing IT systems?

Yes, our solutions take into account the connection of existing machines, systems and software, including legacy systems.

How does GADV support the qualification of my employees?

We offer targeted training and courses to efficiently organise the introduction of new digital tools in your company.

What role does sustainability play in GADV's solutions?

Our solutions help to minimise resource and energy consumption and thus improve the ecological efficiency of your production.