IBM Engineering Lifecycle Management

FMEA interface

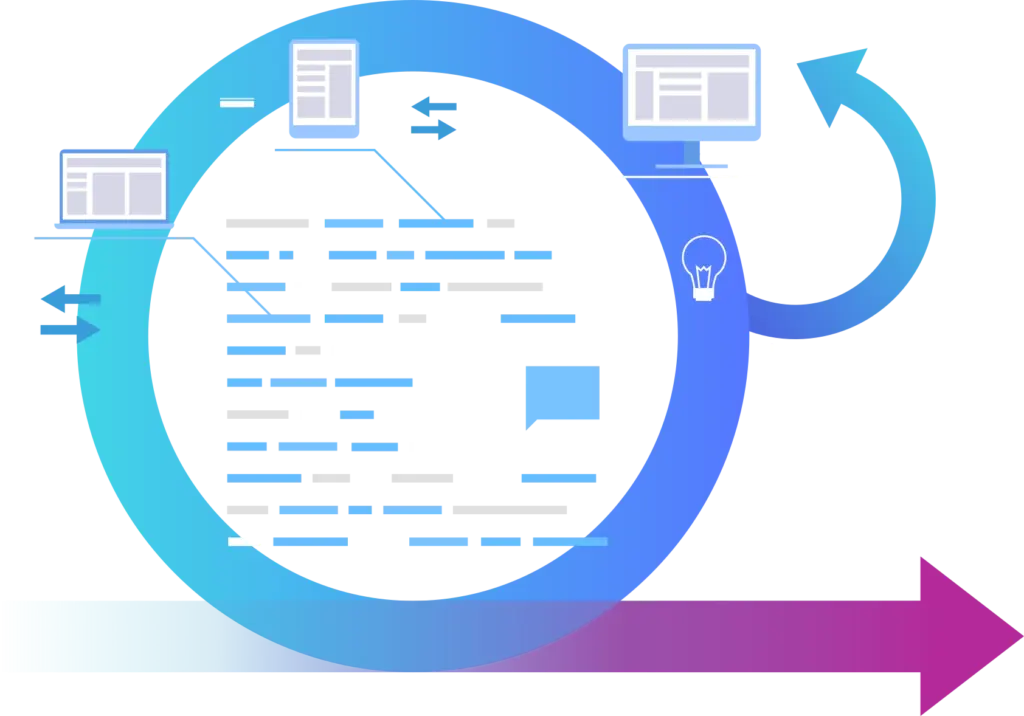

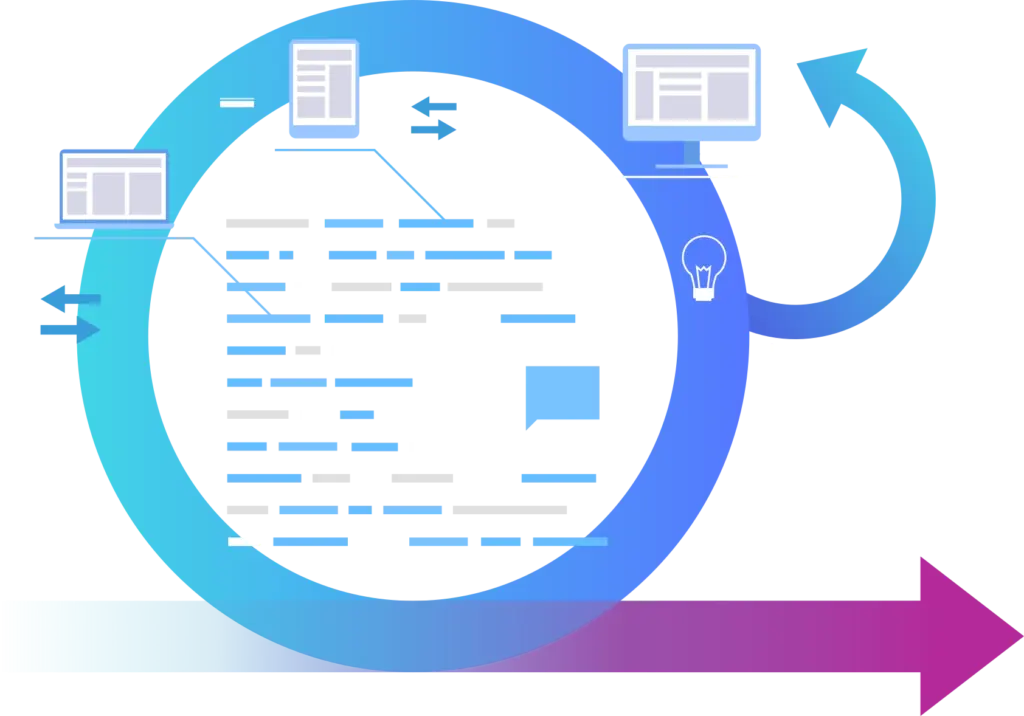

GADV has developed a unique software module that seamlessly integrates Failure Mode and Effects Analysis (FMEA) into the IBM Engineering Lifecycle Management (ELM). This exclusive module automates numerous processes and prevents unnecessary duplication of work, which can reduce development times by up to 20%. With the GADV FMEA interface, we enable automated data exchange that replaces manual transfer and reduces sources of error.

Advantages and functions of the GADV FMEA interface

The GADV FMEA interface offers time optimisation of up to 20 % as well as additional functionalities such as reporting, evaluations, archiving and cross-site document allocation. This integration forms the basis for traceability, impact analyses and compliance with standards such as ISO 26262, IEC 61508 and ISO 60601. We also offer customised configurations of standard tools for resource or budget planning and take care of function and interface adaptations with APIs such as OSLC and REST.

Our solution offers two variants for integrating your FMEA software:

- Integration in IBM Engineering Workflow Management (EWM)

- Integration in IBM Engineering Requirements Management (ERM) DOORS/DOORS Next

Both variants enable bidirectional data exchange via the GADV interface.

Key features of the integration with IBM EWM include the mapping of FMEA versions and measures as work items, process initiation via status changes, automated connection and archiving, as well as interfaces to other applications such as product databases and KPI management.

When integrating with DOORS or DOORS Next, the contents of the FMEA are adopted as requirements according to the rules you have defined.

Request further information or a live demonstration now.

Frequently asked questions (FAQs)

What is the GADV FMEA interface?

The GADV FMEA interface is a specialised module for the seamless integration of FMEA (Failure Fashion and Effects Analysis) in IBM Engineering Lifecycle Management (ELM).

What advantages does the FMEA interface offer?

It reduces sources of error, avoids duplicate data acquisition, automates processes and can shorten development times by up to 20 %.

Which IBM tools are supported?

The integration takes place in IBM Engineering Workflow Management (EWM) and IBM Engineering Requirements Management (DOORS/DOORS Next).

How does the integration into IBM EWM work?

FMEA versions and associated measures are mapped as work items. Status changes trigger automated processes, while tasks are automatically linked and archived

What does the integration with DOORS/DOORS Next do?

FMEA contents are according to defined rules adopted as requirements and fully integrated into the Requirements-management process to ensure traceability.

Which standards are supported?

The interface supports important standards such as ISO 26262, IEC 61508 and ISO 60601 - relevant for functional safety and regulatory requirements.

Can other tools also be connected?

Yes, the interface can be connected to external systems such as product databases or KPI tools via APIs such as OSLC or REST.

Does GADV offer customisation?

We configure standard tools and interfaces according to customer requirements and offer customised adaptations.

What additional functions does the interface offer?

Besides The integration includes the interface reporting, analyses, archiving options and cross-location document linking.

Why should the FMEA interface be integrated into the development process?

Because it promotes structured and standardised work, reduces development times and increases the quality and safety of complex products.